It has also meant that it is now harder to get a high slip resistance rating. Michael Karakolis, Fibonacci Stone’s director, explains that these changes in testing have resulted in the need for new classifications coding that makes it clear that products meet the new standard. Measurements do now allow for the use of brand Uvex shoes and new ST version of calibration boards in addition to the same shoes and test panels as the 2004 version.įibonacci Stone's Platinum Honed Bambra Road achieves a P4 rating Rating goes from R9 to R13, with R9 indicating the lowest slip resistance.

Wet Pendulum Slip Resistance Test – P-rating: the test foot is now conditioned using a polishing film, which is a closer representation of a worn and polished heel, and smoother than the previously used rough sandpaper.However, updates were made in June 2013, which affect how products are being tested.ĪS/NZS 4586:2013 specifies four test methods to determine the slip resistance of products: The Australian slip resistance standards AS 4586 (slip resistance classification of new pedestrian surface materials) and AS 4663 (existing pedestrian surfaces) are the main benchmarks for the industry. “The slip rating of the new marble floor finishes was difficult to confirm even though it had been specifically detailed in the tender documents,” practice director Megan Jones told A&D, adding that the specified natural Carrara tiles were required to have a slip resistance compliant to AS/NZS 4586. Tanner Kibble Denton Architects is one practice that has addressed the challenge of ensuring the floors are truly safe for pedestrians in their Brisbane City Hall Restoration project.

With all these contributing elements, getting slip resistance right is invariably a complex issue. This slip hazard is influenced by a range of factors, including the nature and function of the surface, its wear characteristics, footwear or the lack of maintenance requirements, the presence of slopes, and environmental conditions such as exposure to water.īrisbane City Hall Restoration by Tanner GHD.

#Goldilocks principle install#

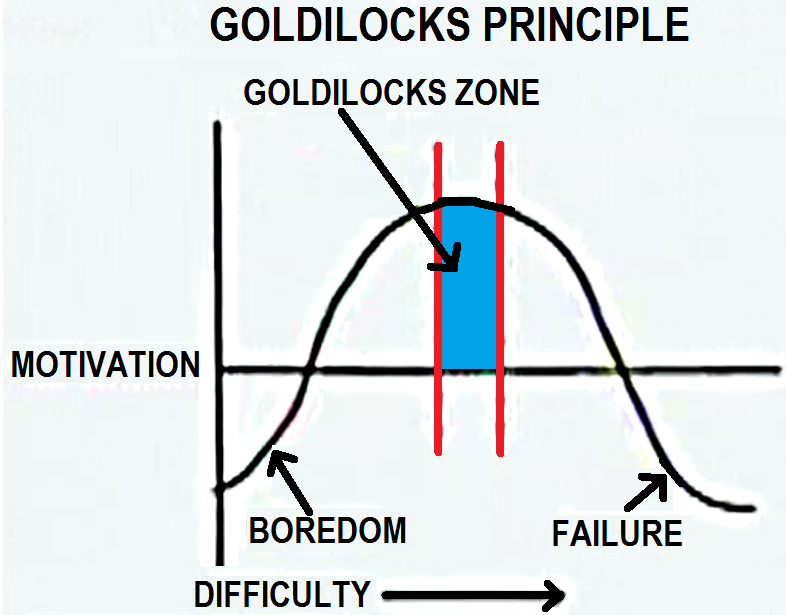

In Australia, the best way to ensure a floor is safe is to specify and install a material that meets or exceeds the current Australian Standards (AS), which refer to the slip resistance of a surface as the surface’s ability to reduce or prevent the risk of a person slipping. “People want to live in safe homely environments, not with senselessly mandated semi-industrial flooring,” Bowman writes. “It is important that one gets it just right – not too slippery, and not too slip resistant.”īowman notes that with this idea of specifying floors that are ‘just right’ – the ‘Goldilocks Principle’, specifying greater slip resistance might not be the most effective panacea. “Most of the problems we have seem to revolve around people assuming that more slip resistance is better, but too much slip resistance can be worse,” says Intertile Research’s managing director Richard Bowman, who is also a keynote speaker at Australia’s inaugural Universal Design conference. Ensuring that people will be safe from slips, trips and falls in the spaces they occupy is an important part of the design process, with designers, manufacturers, contractors and architects having to specify floor products that comply with appropriate slip resistance levels.īut, what exactly are the most appropriate slip resistance levels? Sticks and stones may break your bones…but slips and falls can too. Exhibitions, Associations & Information.Ceilings, Internal Wall Materials & Partitioning.

0 kommentar(er)

0 kommentar(er)